Sometimes, a real no-brainer, problem-solver of a product can crash and burn spectacularly upon entering the market. This isn’t limited to the Pepsi Clears of the world, where sheer ridiculousness doomed the idea from the start: According to Nielsen data, 85 percent of new consumer packaged goods will fail within two years. Marketing snafus, bad luck and timing aside, pitfalls in the process of product design are often to blame. Catching oneself before blundering into them takes a conscious effort, as several local designers and makers illustrate.

1. Know when to Stop

The original Swiss Army knife, designed in the late 1890s, compactly bore two blades, a fabric reamer, can-opener, screwdriver and a corkscrew. One of the most recent models today features 87 implements and weighs seven pounds — no longer a handy quick-fixer. What keeps a design from running off the rails is restraining the urge to just keep tinkering beyond what’s necessary and instead get the product into the field for users to test.

“Sometimes it’s hard to know when to quit working on [a project],” says Jerry McCall, founder and CEO of Stikwood, an interior decor company that produces stick-on wood paneling. “In many cases, because I’m constantly imagining new features, it’s very easy to get caught up in adding things. There’s no clear indicator to me that says, ‘Hey, that’s enough,’ essentially separating myself from the creative endeavor to the commercial design process.”

Blending forward-thinking design with timeless aesthetics is one of the challenges in not over-designing a product on the way to market. Trends can change with taste and time, so don’t wholly foresake simplicity.

2. Be a forward-thinker

Most products that launch prematurely are forgotten quickly, although they can resurface. Consider the IBM WatchPad in 2001 — a clunkier, slower version of the Apple Watch so popular today. It had a battery life of just a few hours and a 320×240-pixel screen displaying Linux; it barely did anything more than a regular digital watch. The company lost out in the end by letting the rush to be first take priority over fully developing their tech.

Related: Function with Flair

The ways internet-based products like websites, databases or networks are consumed is always evolving, redefining what makes a product versus a service. Website and database creation itself has been considered a product for some time in the industry, with services like tech support or hosting packaged along with the digital product. Another step forward combines products with services to create integrated platforms.

“When we started, we systematized the delivery of service; we built a 5-stage process which started to build a product around the delivery of service so it could be consistent, profitable and scalable,” says Mac Clemmens, co-founder and CEO of web development company Digital Deployment. “Now we’re able to produce websites for a fraction of the cost … Platforms like this are really the economy of the future. It’s like product 2.0: A platform connects the buyer and seller immediately, so eBay, for example, isn’t a website product but a true platform.”

Digital Deployment, based in midtown Sacramento, focuses on content management systems: websites and databases for complex organizations like the Sacramento City Unified School District and California Children’s Hospital Association. These platform products are designed to be easy to use internally with customizable external use, whether that be unique aesthetics or specific functionalities. “Poor design usually means design that doesn’t have clear priorities,” Clemmens says. “Sites that we might think of as ugly, like Craigslist or Reddit, might not change their fonts or be image-heavy, but often they’ve made a lot of data-driven design decisions to work perfectly for their intended end-users.”

3. Consider manufacturing past the prototype

Ensuring a market-ready product can appeal to actual consumers means doing the extra work of feasibility testing and investing in quality materials. What works on the drawing board does so without the encumbrance of physical construction, the limitations of actual materials and the fickleness of user interaction. Getting the real thing to work means ironing out design kinks through every iteration before declaring a design complete.

JDID Product Design & Development is a Sacramento firm dedicated to taking a concept from ideation into a useable product. They work with inventors on everything from the initial design to testing and packaging for a variety of products including medical devices, bicycle parts, hydroponic systems and high-durability mobile device cases. Principal and lead designer Jubal DeLong notes that the nuances of prototyping and testing have a significant impact on a design’s effectiveness.

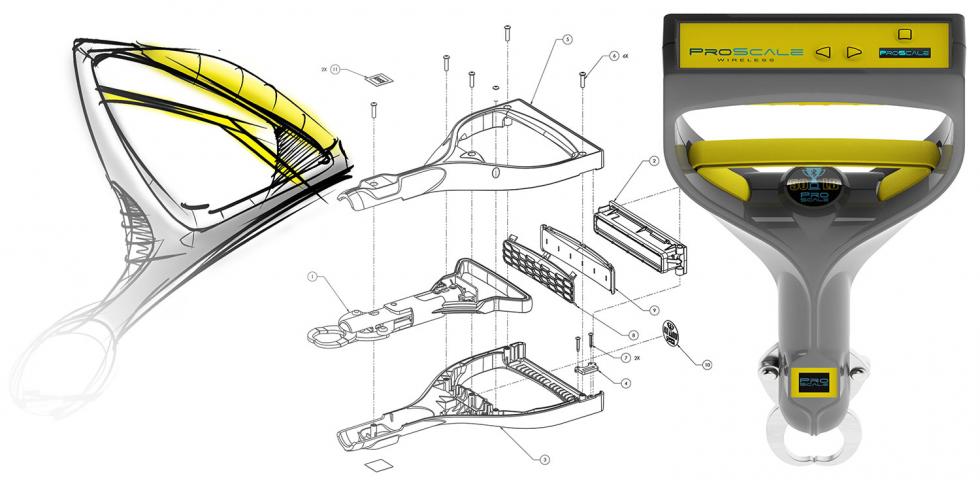

JDID’s ProScale is the world’s first Bluetooth-enabled accessory

for catch-and-release fishermen. Jubal Delong calls it a “virtual

tacklebox” that, among other features, measures fish and logs

weather conditions. Anglers can, in real time, share images and

data of their catches via text or social media.

“Design for proof-of-concept [functionality] or prototype is typically hugely different than design for manufacturing. POC models may be down and dirty so long as they’re constructed in such a way as to reliably prove, illuminate or disprove particular aspects of a solution. They may be torn-down, hacked and modified into the next round of developmental evaluation or testing.”

But, according to DeLong, producing the final version requires more thought and delicacy in detail. “The best design for manufacture serves an entirely different purpose and should be responsible to as many business units as possible,” he says. “At JDID we think of our deliverables as spherical — that is to say accountable to as many business units within our clients’ organization as possible.

4. Differentiate yourself from competitors

Even consumables like food and drink are crafted with a purpose in mind. A “well-designed menu” is a compliment often given to restaurants — indicating the overall dining experience, rather than just the food itself, makes the product. Coca-Cola tries to position its product similarly, with ads that sell the experience of drinking a Coke over the actual product itself.

Silk Road Soda, headquartered in Roseville, produces a modern take on an ancient vinegar-fermented beverage not familiar to most Western consumers. Authenticity is key to transcending that unknown aspect in the consumer’s mind to make the product a success.

“The flavors for Silk Road follow the cultures of the region I’m from,” says Payam Fardanesh, co-founder of Silk Road Soda. “I wanted to represent the amazing history and culture of the Silk Road and of my home country of Iran. For example, my Cucumber Mint flavor comes directly from my Persian heritage. We used to shave cucumbers into the base syrup called sekanjabin, and then added water. Our newest flavor Ginger Mint, is how the Greek culture drinks the drink: it is called Oxymel and uses honey.”

The beverage market is a crowded space, and a new product must offer something different — even when that novelty is actually rooted in tradition — to win out over products that lack a deliberate, authentic identity.

5. Reduce Complexity

“I’m always looking for simple answers to complicated problems,” says Stikwood’s McCall. “I tend to discover features that create unplanned benefits for the user. Any feature that creates multiple benefits is also a huge plus. And of course, if it involves someone having to do something, I’m always finding ways to respect the time of the user.”

Creating a seamless user experience is an iterative process. The initial drawing, model and prototype are all for the creator’s benefit, but eventually real people have to engage with the product to see if any human factor was missed in design. Materials and production processes can alter a design that was flawless on paper.

McCall seems to enjoy this part of product design the most. “I’ll imagine how [the product] would work; I try to see the material, see the texture, feel what it’s going to look like, then test it in the real world through trial and error and R&D,” he says. “During the R&D process is when I start to eliminate some of the complexity that I’ve developed in my mind.”

Buckminster Fuller, radical architect and inventor in the mid-last century, liked to say of his work: “I look for what needs to be done. After all, that’s how the universe designs itself.” A generation later, fellow designer and sustainability pioneer William McDonough would note that “design is the first sign of intent.” We are surrounded by design every day, from the beds we sleep on to the tools we use to do our jobs. Products with sound design that make it to market only do so by avoiding pitfalls which take design off-target or out of context, or increase the complexity of a problem rather than solving it.