One of the largest wood-manufacturing companies in California, Sierra Pacific Industries started with a small sawmill on the North Coast. Founded by “Curly” Emmerson in 1979 and followed by his son “Red,” the company now employs approximately 3,800 people.

Not only does it produce doors and windows, it also produces a better habitat by managing forests in California and Washington State. And the type of harvesting that SPI does simulates nature’s own methods.

“We kind of mimic what happens naturally in the forest, that way you have healthy, sustainable forests for generations to come,” says Mark Luster, Sierra Pacific’s community relations manager. That includes controlled burning to harvest trees in certain locations — the same way natural fires would clean up vegetation.

This level of forest management requires a crew of scientists. But determining the value of a log is left to log-scalers like Anthony Kitchen, shown here measuring the volume and value of each piece.

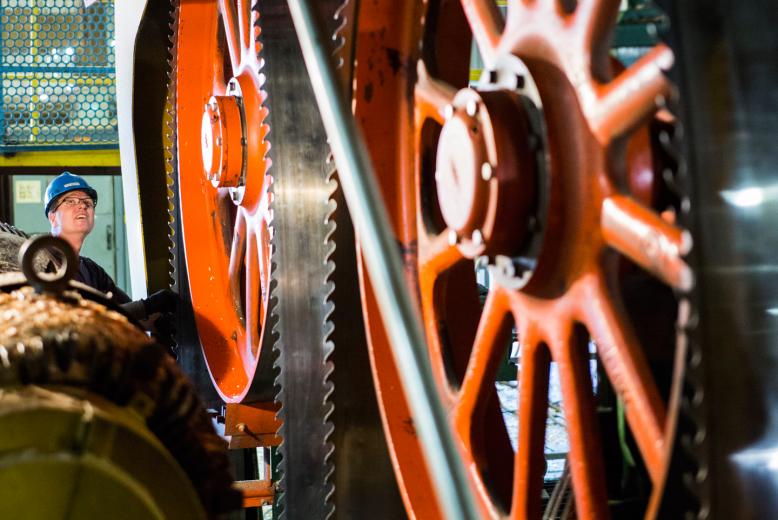

In order to make a straight, smooth cut through the core of a tree, loggers at Sierra Pacific Industries must keep their massive saw blades sharp. Equipment Operator Brandon Rogers helps saw-filer Scott Andersen change out a worn blade.

It can take at least two men to wrangle a blade into the room where it will be sharpened, but they use a lift machine to move the “fairly heavy” saw. Having employees on site to fabricate sawmill equipment (some of whom have been with the company for more than 25 years) keeps the business moving.

“There’s a significant amount of room for growth,” says Mark Luster, the company’s community relations manager. “We do a lot of promotion from within, so if an individual has the skill set and the work ethic, there’s lots of opportunities.”

Turning trees of the forest into doors for homes is “a very complicated process,” says Mark Luster, the community relations manager for Sierra Pacific Industries, a 34-year-old logging company based in Lincoln. “It takes a lot of skilled folks and in some cases years to produce products.”

Running the logs through a computerized laser scanner, manufacturers can measure to a thousandth of an inch. Butch Tittle, an off-bearer, looks at the logs and determines where to send the sawed pieces based on size and grade.

Logs are then sent through another round of precision cutting, and 100 percent of the tree is used. “We take the saw dust, we use it. We take the bark, we use it. We have a cogeneration power plant — even the ash from the power-plant gets sold,” Luster says.

Photos: Ken James Captions: Isabel Ward

Sawing Logs

Blade Running with Sierra Pacific Industries